SolidWorks Simulation- Mesh Controls

SolidWorks Simulation- Mesh Controls , SolidWorks Simulation- Mesh Controls

SolidWorks Simulation- Shell Symmetry Fixture

SolidWorks Simulation- Shell Symmetry Fixture SolidWorks Simulation- Shell Symmetry Fixture

SolidWorks Simulation- Advanced Restraints

SolidWorks Simulation- Advanced Restraints , SolidWorks Simulation- Advanced Restraints

SolidWorks Simulation- Easy Results Plot Editing

SolidWorks Simulation- Easy Results Plot Editing SolidWorks Simulation- Easy Results Plot Editing

SolidWorks Simulation- Flow Simulation Lids Video

SolidWorks Simulation- Flow Simulation Lids Video , SolidWorks Simulation- Flow Simulation Lids Video

SolidWorks Simulation- Automatic Mixed Mesh

SolidWorks Simulation- Automatic Mixed Mesh , SolidWorks Simulation- Automatic Mixed Mesh

What can SolidWorks SimulationXpress do?

SolidWorks SimulationXpress…it’s FREE! Use it!

(there’s a complimentary bonus link at the end)

(there’s a complimentary bonus link at the end)

What can SimulationXpress do?

General design screening and relative comparisons part design is good place to start. This is an entry level step into simulation based on the full SolidWorks Simulation product allowing industrial designers through engineers to have the ability to perform “Virtual Validation” even with the entry level version of SolidWorks Standard.SimulationXpress Core Capabilities

- Part analysis

- Stress analysis

- Optimization analysis with one variable and criterion

- Analysis management using Simulation study tree

- Isotropic materials

- Uniform pressure and force on faces

- Fixed restraints on faces

- Stress contour plot-equivalent (von Mises) stress

- Deformation plot

- Factor of safety calculation and plot

- Generate reports

- Publish SolidWorks eDrawings of analysis results

- Animate and save as AVI

While not everyone is devoted to being a Finite Element Analysis (FEA) analyst, with SimulationXpress you can develop skills to help optimize design concepts for performance, minimize product weight, and reduce costs of many designs.

And the bonus that you’ve been waiting for… FREE SolidWorks SimulationXpress Training is Available Online!

SolidWorks Simulation, Tech Tips / Simulation Tech Tip: Shakers and Movers

You have created a Simulation study of a fairly large assembly.

It has a mixed mesh – Solid elements, also Shell elements, maybe also

some Beams. You are relying on the GLOBAL CONTACT – BONDED to tie

together all the mesh bodies of similar type. You spent maybe 40

minutes, at least, creating the BONDED contact conditions to tie the

dissimilar mesh elements together.

And now when you try to run the study, you get the failure message, “Zero or indefinite stiffness matrix”.

Ugh. That means that at least one component is not correctly

bonding to a neighbor, and so is free-floating. But which one? Since

the study won’t run, you can’t display the displacement plot, and see

which part(s) are flying off the screen. How to diagnose this – without

wasting the entire morning? There are two ways I approach solving the

problem, and they both use the study Property option, “Use Soft Springs

to Stabilize the Model”.

1: Moving

Sometimes you can simply turn ‘soft springs’ on, and run the study

again. About half the time, I find that the study will now run, (and

produce a warning message, that very large displacements were

detected). Tell it to continue running the study anyway, as-is, without

turning on the large-displacement flag. Then, when you plot the

Displacement results, you might very well be looking at an empty screen,

or you might see that one (or more) parts seem to be missing from the

plot. They are not missing – they simply went flying off the screen.

Set your Displacement scale factor to be wicked small, (think many

leading zeros), and then animate the displacement plot – and you’ll see

at the start of the animation, which parts are un-tethered, and in which

directions they are free to wander.

A cool and easy trick. Except that, I did say above, I use this

trick “about half the time”. Because the other half of the time, the

applied loads might act directly on the under-restrained parts, in the

same direction that they are free to move, and then the “Soft Springs”

do not supply enough stabilization. What to do then?

2: Shaking

The second approach is to Shake the assembly, instead of moving it.

Create a new Modal Study, (this will require the Simulation license to

be Simulation Professional or higher). Set the Modal Study Properties

to only ask for the lowest 2 mode-shapes, or maybe 3, but no more.

(this is a diagnosis, not a true study, so you want it to run fast).

Then you copy all your Restraints and Bonded conditions into the new

study.

Wait – I did NOT say to re-create all your Restraints and Bonded

contacts. I said “COPY” them. This is a “tip within the tip”. A lot

of people I encounter still don’t know you can do this. If you activate

your first, “real” study, you can then select the folder for your

Restraints, and DRAG that folder down to the row of tabs at the bottom

of your screen, and DROP it into your new Modal study. Done. So

creating this Modal study to diagnose your problem should take, like, 30

seconds tops. You do NOT have to copy over your system of loads –

just the restraints and bonding, because we are not going to ‘push’ your

assembly in any particular direction, we are instead going to vibrate

it in-place.

But, you DO still have to turn on the “Soft Springs” option to stabilize the model.

Ok, now you RUN the Modal study. Because the underlying equations

of the Modal study are being solved differently than a Static study, the

problem will generally solve O.K. even with under-supported parts.

And, when you activate the plot for the lowest 2 or 3 mode-shapes, each

one should show you some rigid-body motion, (and remember, it could also

be a rotation!), of the part or parts that are un-tethered. Animate

the model-shape plot, and it will be patently obvious which parts are

walking away, and in which directions.

Important caveat: The Modal Analysis method of diagnosing your

problem, will NOT allow you to create sliding or intermittent Contact

via the “No Penetration” gap elements. If your problem also has that

kind of Contact in it, you need to either ignore that contact for the

purpose of diagnosis, (which will too sloppy, and you’ll have to ask for

more Mode Shapes – ignore the responses you know are not ‘real’);

Or, you could replace the Bonded contact, with either an Elastic

Support, or a Spring Connector. With either of these, make the Normal

spring stiffness pretty high, but the tangential spring stiffness very

low – and you WILL have over-supported the selected faces a little bit.

But again, you’re just looking for which parts want to walk away, not

running the ‘real’ study yet, so we can throw a few darts. And if the

problem produces NO rigid-body modes when you’ve replaced the Gap

elements with springs, then you know for sure that the Contact

conditions are the real problem.

One of these two methods should solve the “Zero or Indefinite Matrix” problem for you, just about all the time.

Three New SolidWorks Simulation Functions in 2013

Shell Edge to Beam Bonding

The

bonding of shell edges that belong to surface or sheet metal bodies to

beams, commonly used to simulate gusset plates connecting beams, is

supported through manual contact set definitions.

The

bonding of shell edges that belong to surface or sheet metal bodies to

beams, commonly used to simulate gusset plates connecting beams, is

supported through manual contact set definitions.To create a shell edge to beam bonded contact, in the Contact Sets PropertyManager, under Type, select Bonded. For Set 1, click Beams and select the beam from the graphics area. For Faces, Edges for Set 2, select the shell edge.

Render Shell Thickness

You can display the mesh and results of shells using a 3D representation of shall bodies. There is a new option to display the thickness of shells in result plots (stress, displacement, and strain) and when viewing the mesh.To view the results on a 3D representation of shell bodies, in a Stress Plot, Displacement Plat, or Strain Plot PropertyManager, Under Advanced Options, select Render shall thickness in 3D (slower).

The shell thickness displayed in the plots is the value defined in the Shell Definition PropertyManger. The orientation of thickness is displayed with relation to the midsurface of the shell, as defined by the offset value (Shell Definition PropertyManager).

For stress plots, results for the top and bottom shell faces are shown. Results are literally interpolated across the shell thickness. When probing stress plots, both the top and bottom shell values are displayed.

Reaction Forces for Beams

You can list the reaction forces and reaction moments at beam joints that have fixed translation or rotations.

In the Result Force PropertyManager, under Selection, select the beam joint to list the reaction forces.

Want to read more? Download the SolidWorks Simulation 2013 Datasheet.

Where to find SolidWorks Simulation Tutorials

A recent sales promotion has helped many new customers obtain a license of SolidWorks Premium, which includes lots of great Add-in functionality beyond SolidWorks Standard and SolidWorks Professional. Perhaps the most popular is SolidWorks Simulation,

which provides full finite element analysis (FEA) capabilities for

linear static (“stress/strain”) simulation. Also, those of you on a

“floating” Network License may have access to a Simulation license. But

many of you might not know how or where to get started with Simulation.

Where are the SolidWorks Tutorials? Where is the Help?

Well, Step 0 is you need to make sure SolidWorks Premium is

installed! If it is not, then you won’t be able to do Step 1. If you

need help installing (or modifying your current installation), then

contact your CAD Administrator, or CAPINC customers on subscription can

of course contact our Technical Support staff.

Step 1: Turn on the “SolidWorks Simulation” Add-in. Launch SolidWorks and navigate to the Tools > Add-Ins… menu:

Check the left-hand box to turn on Simulation in this session.

Checking the right-hand box will turn it on in every session from now

on, which if you’re using a Network License may anger your coworkers who

might want access to the license that you’ll keep grabbing!

Step 2: Open a Part or Assembly file. You will not

see any Simulation user interface (icons or toolbars) unless a model

file is open. It can be a new empty file, as long as you have one open.

Step 3: Browse the pull-down menus (usually hidden beneath the SolidWorks logo) to Simulation > Help > Tutorials. You could also browse instead to Help > SolidWorks Simulation > Tutorials. As long as the Add-In is on, and a model file is open, you will be able to see both of these menu options.

|

|

I recommend getting started with the Tutorials. Similar to SolidWorks CAD Tutorials, they divide the screen into two regions and give you easy click-by-click instructions for opening files and going through some steps to acquaint yourself with basic Simulation functionality. SolidWorks Premium includes Simulation Statics. Incidentally, SolidWorks Premium also includes Motion Simulation, but that’s for another post on another day…

After completing a few Tutorials, your next step is to try some of your own simple examples. Then if you decide you want to start using Simulation for your design work, you should attend a Simulation course at CAPINC. We offer a 3-day class for designers to become productive with SolidWorks Simulation. We begin with the essentials of FEA and end with the nonlinearities of large-displacement solutions! (It sounds complicated, but it’s just a check-box option!) The 3rd day of class covers the additional study types available with Simulation Professional (Thermal, Frequency, Buckling, Fatigue, and Drop Test).

SolidWorks Simulation Professional Fatigue

My company does not want to upgrade to EPDM; but they want to create a vaulting system which will index all files.

I have been researching programs such as DBWorks, Conisio…

I’m looking for comparable programs, or any extra info would be appreciated.

Statement below is info from my VAR about SolidWorks Explorer and our 64 bit’s

~As is mentioned in many Microsoft forums, this is a Microsoft Windows limitation. Mapped, network locations cannot be indexed by Windows Search on Windows Vista x64 or Windows 7 x64, therefore they cannot be added to SolidWorks Explorer's search paths list. To workaround this limitation, you can make the files stored in the mapped, network location available offline. Files that are made available offline can be indexed by Windows Search and can therefore be added to the search files list since they will be stored locally. Search the Windows Help for "sync offline files" for more information on how to setup offline files.

476452 - Cannot enable Indexing service search for Workgroup PDM on Windows Server 2008 64-bit, Windows Server 2008 R2 64-bit, Vista 64-bit and Windows 7 64-bit operating systems – open - Until this is achieved we cannot consider Workgroup as being fully supported on Windows Server 2008. Please see KB S-054407 for manual methods to enable Indexing for the Operating systems in question.

For SPR 476452 there will not be a Service Pack or future version delivered solution available for this limitation. However, SolidWorks Development and Technical Support have developed the attached instructions for a workaround which will configure these operating systems to enable the Indexing Service to work in concert with SolidWorks Workgroup PDM Search. These instructions do require changes to be made in the Window registry which should be done with caution and only by individuals comfortable with making registry edits~

SolidWorks Simulation Professional Drop Test

Solidworks Simulation Tutorial With Heat Exchanger Efficiency

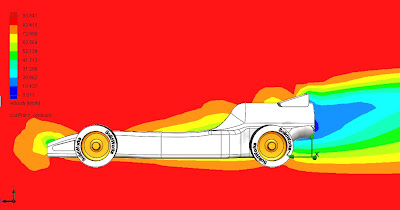

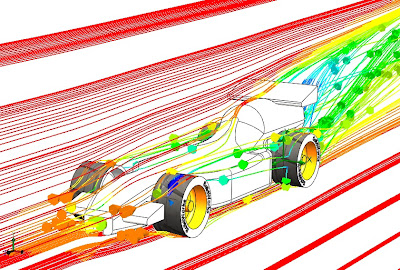

Solidworks Flow Simulation can be used to study the fluid flow and heat transfer for a wide variety of engineering equipment. In this example we use Solidworks Flow Simulation to determine the efficiency of a counterflow heat exchanger and to observe the temperature and flow patterns inside of it. With Solidworks Flow Simulation the determination of heat exchanger efficiency is straightforward and by investigating the flow and temperature patterns, the design engineer can gain insight into the physical processes involved thus giving guidance for

improvements to the design.

A convenient measure of heat exchanger performance is its “efficiency” in transferring a given amount of heat from one fluid at higher temperature to another fluid at lower temperature. The efficiency can be determined if the temperatures at all flow openings are known. In Solidworks Flow Simulation the temperatures at the fluid inlets are specified and the temperatures at the outlets can be easily determined. Heat exchanger efficiency is defined as follows:

The actual heat transfer can be calculated as either the energy lost by the hot fluid or the energy gained by the cold fluid. The maximum possible heat transfer is attained if one of the fluids was to undergo a temperature change equal to the maximum temperature difference present in the exchanger, which is the difference in the inlet temperatures of the

The goal of the project is to calculate the efficiency of the counterflow heat exchanger. Also, we will determine the average temperature of the heat exchanger central tube’s wall. The obtained wall temperature value can be further used for structural and fatigue analysis.

Open the Model Solidworks Simulation Tutorial With Heat Exchanger Efficiency

Click File, Open. In the Open dialog box, browse to the Heat Exchanger.SLDASM assembly located in the Tutorial 3 - Heat Exchanger folder and click Open (or doubleclick the assembly). Alternatively, you can drag and drop the Heat Exchanger.SLDASM file to an empty area of SolidWorks window.

Get File Pdf Solidworks Simulation Tutorial With Heat Exchanger Efficiency

Determination of Hydraulic Loss in Solidworks Flow Simulation

Determination of Hydraulic Loss in Solidworks Flow Simulation

In engineering practice the hydraulic loss of pressure head in any piping system is traditionally split into two components: the loss due to friction along straight pipe sections and the local loss due to local pipe features, such as bends, T-pipes, various cocks, valves, throttles, etc. Being determined, these losses are summed to form the total hydraulic loss. Generally, there are no problems in engineering practice to determine the friction loss in a piping system since relatively simple formulae based on theoretical and experimental investigations exist. The other matter is the local hydraulic loss (or so-called local drag). Here usually only experimental data are available, which are always restricted due to their nature, especially taking into account the wide variety of pipe shapes (not only existing, but also advanced) and devices, as well as the substantially complicated flow patterns in them.

Flow Simulation presents an alternative approach to the traditional problems associated with determining this kind of local drag, allowing you to predict computationally almost any local drag in a piping system within good accuracy. Click File, Open. In the Open dialog box, browse to the Valve.SLDPRT model located in the Tutorial 1 - Hydraulic Loss folder and click Open (or double-click the part). Alternatively, you can drag and drop the Valve.SLDPRT file to an empty area of the SolidWorks window.

Model Description

The standard engineering convention for determining local drag is by calculating the difference between the fluid dynamic heads measured upstream of the local pipe feature (ball valve in our case) and far downstream of it, where the flow has become uniform (undisturbed) again. In order to extract the pure local drag the hydraulic friction loss in the straight pipe of the same length must be subtracted from the measured dynamic head loss. In this example we will obtain pressure loss (local drag) in the ball valve whose handle is turned by an angle of 40o. The Valve analysis represents a typical Flow Simulation internal analysis.

Internal flow analyses deal with flows inside pipes, tanks, HVAC systems, etc. The fluid enters a model at the inlets and exits the model through outlets. To perform an internal analysis all the model openings must be closed with lids, which are needed to specify inlet and outlet flow boundary conditions on them. In any case, the internal model space filled with a fluid must be fully closed. You simply create lids as additional extrusions covering the openings. In this example the lids are semi-transparent allowing a view into the valve

To ensure the model is fully closed click Flow Simulation, Tools, Check Geometry. Then click Check to calculate the fluid and solid volumes of the model. If the fluid volume is equal to zero, the model is not closed. Click Fluid Volume to see the volume that will be occupied by fluid in the analysis. Uncheck Fluid Volume. Close the Check Geometry dialog box.

The Check Geometry tool allows you to calculate the total fluid and solid volumes, check bodies for possible geometry problems (i.e. invalid contact) and visualize the fluid area and solid body as separate models. The first step is to create a new Flow Simulation project

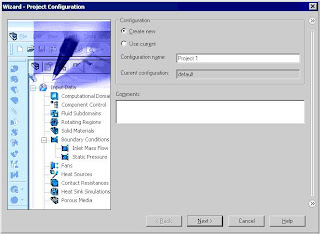

1 Click Flow Simulation, Project, Wizard. The project wizard guides you through the definition of a new Flow Simulation project.

2 In the Project Configuration dialog box, click Use current. Each Flow Simulation project is associated with a SolidWorks configuration. You can attach the project either to the current SolidWorks configuration or create a new SolidWorks configuration based on the current one. Click Next.

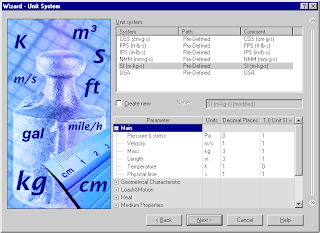

3 In the Unit System dialog box you can select the desired system of units for both input and output (results). For this project use the International System SI by default. Click Next.

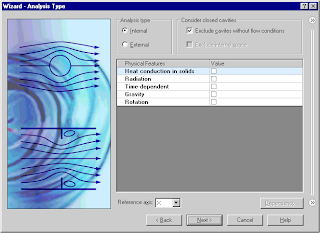

4 In the Analysis Type dialog box you can select either Internal or External type of the flow analysis. To disregard closed internal spaces not involved in the internal analysis, you select Exclude cavities without flow conditions. The Reference axis of the global coordinate system (X, Y or Z) is used for specifying data in a tabular or formula form in a cylindrical coordinate system based on this axis.

This dialog also allows you to specify advanced physical features you may want to take into account (heat conduction in solids, gravitational effects, time-dependent problems, surface-to-surface radiation, rotation). Specify Internal type and accept the other default settings.

Click Next.

Since we use water in this project, open the Liquids folder and double-click the Water item. Engineering Database contains numerical physical information on a wide variety of gas, liquid and solid substances as well as radiative surfaces. You can also use the Engineering Database to specify a porous medium. The Engineering Database contains pre-defined unit systems. It also contains fan curves defining volume or mass flow rate versus static pressure difference for selected industrial fans. You can easily create your own substances, units, fan curves or specify a custom parameter you want to visualize.

Click Next.

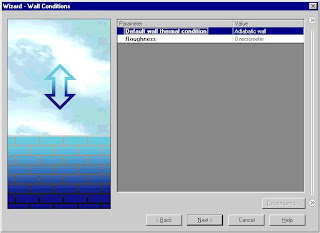

6 Since we do not intend to calculate heat conduction in solids, in the Wall Conditions dialog box you can specify the thermal wall boundary conditions applied by default to all the model walls contacting with the fluid. For this project accept the default Adiabatic wall feature denoting that all the model walls are heat-insulated. In this project we will not consider rough walls. Click Next.

7 In the Initial Conditions dialog box specify initial values of the flow parameters. For steady internal problems, the specification of these values closer to the expected flow field will reduce the analysis convergence time.

For steady flow problems Flow Simulation iterates until the solution converges. For unsteady (transient, or time-dependent) problems Flow Simulation marches in time for a period you specify. For this project use the default values. Click Next

8 In the Results and Geometry Resolution dialog box you can control the analysis accuracy as well as the mesh settings and, through them, the required computer resources (CPU time and memory). For this project accept the default result resolution level 3.

Result Resolution governs the solution accuracy via mesh settings and conditions of finishing the calculation that can be interpreted as resolution of calculation results. The higher the Result Resolution, the finer the mesh and the stricter the convergence criteria. Naturally, higher Result Resolution requires more computer resources (CPU time and memory).

Geometry Resolution (specified through the minimum gap size and the minimum wall thickness) governs proper resolution of geometrical model features by the computational mesh. Naturally, finer Geometry Resolution requires more computer resources. Select the Manual specification of the minimum gap size check box and enter 0.04 m for the Minimum gap size.

Flow Simulation calculates the default minimum gap size and minimum wall thickness using information about the overall model dimensions, the computational domain, and faces on which you specify conditions and goals. However, this information may be insufficient to recognize relatively small gaps and thin model walls. This may cause inaccurate results. In these cases, the Minimum gap size and Minimum wall thickness must be specified manually. Click Finish.

Create a Flow Simulation Project in Solidworks

In Flow Simulation Project in Solidworks we consider flow in a section of an automobile exhaust pipe, whose exhaust

flow is resisted by two porous bodies serving as catalysts for transforming harmful carbon

monoxide into carbon dioxide.

Open the SolidWorks Model

1 Click File, Open.

2 In the Open dialog box, browse to theCatalyst.SLDASM assembly located inthe First Steps - Porous Media folderand click Open (or double-click theassembly). Alternatively, you can dragand drop the Catalyst.SLDASM file to an empty area of SolidWorks window.

When designing an automobile catalytic converter, the engineer faces a compromise between minimizing the catalyst's resistance to the exhaust flow while maximizing the catalyst's internal surface area and duration that the exhaust gases are in contact with that surface area. Therefore, a more uniform distribution of the exhaust mass flow rate over the catalyst's cross sections favors its serviceability

. The porous media capabilities of Flow Simulation are used to simulate each catalyst, which allows you to model the volume that the catalyst occupies as a distributed resistance instead of discretely modeling all of the individual passages within the catalyst, which would be impractical or even impossible.

Here, as a Flow Simulation tutorial example we consider the influence of the catalysts' porous medium permeability type (isotropic and unidirectional media of the same resistance to flow) on the exhaust mass flow rate distribution over the catalysts' cross sections. We will observe the latter through the behavior of the exhaust gas flow trajectories distributed uniformly over the model's inlet and passing through the porous catalysts. Additionally, by coloring the flow trajectories by the flow velocity the exhaust gas residence time in the porous catalysts can be estimated, which is also important from the catalyst effectiveness viewpoint.

Boundary Conditions Solidworks Flow Simulation Tutorial

Boundary Conditions Solidworks Flow Simulation Tutorial help you learn something

A boundary condition is required anywhere fluid enters or exits the system and can be

set as a Pressure, Mass Flow, Volume Flow or Velocity.

1 In the Flow right-click the Boundary Conditions icon

Simulation Analysis Tree,

2 Select the inner face of the Lid <1> part as

shown. (To access the inner face, right-click

the Lid <1> in the graphics area and choose

Select Other , hover the pointer over

items in the list of items until the inner face

is highlighted, then click the left mouse

button).

3 Select Flow Openings and Inlet Mass Flow.

5 Click OK . The new Inlet Mass Flow 1 item

appears in the Flow Simulation Analysis tree.

With the definition just made, we told Flow Simulation that at this opening 0.5

kilogram of water per second is flowing into the valve. Within this dialog box we can

also specify a swirl to the flow, a non-uniform profile and time dependent properties to

the flow. The mass flow at the outlet does not need to be specified due to the

conservation of mass; mass flow in equals mass flow out. Therefore another different

condition must be specified. An outlet pressure should be used to identify this

condition.

6 Select the inner face of the Lid <2> part as

shown. (To access the inner face, right-click

the Lid <2> in the graphics area and choose

Select Other , hover the pointer over items

in the list of items until the inner face is

highlighted, then click the left mouse button).

7 In the Flow Simulation Analysis Tree, rightclick

the Boundary Conditions icon and

select Insert Boundary Condition.

Select Pressure Openings and Static Pressure.

9 Keep the defaults in Thermodynamic Parameters,

Turbulence Parameters, Boundary Layer and Options group boxes.

10 Click OK . The new Static Pressure 1 item appears in

the Flow Simulation Analysis tree.

With the definition just made, we told Flow Simulation that at this opening the fluid exits the model to an area of static atmospheric pressure. Within this dialog box we can also set time dependent properties to the pressure.

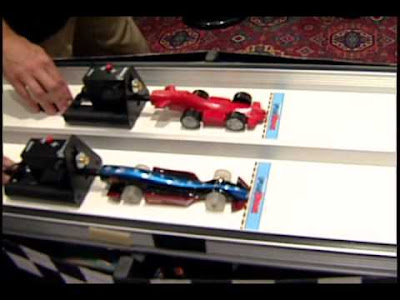

First Steps - Ball Valve Design in Solidworks Flow Simulation tutorial

Flow Simulation solidworks tutorial

This First Steps tutorial covers the flow of water through a ball valve assembly before and

after some design changes. The objective is to show how easy fluid flow simulation can be

using Solidworks Flow Simulation and how simple it is to analyze design variations. These two factors make Solidworks Flow Simulation the perfect tool for engineers who want to test the impact of their design changes.

1 Copy the First Steps - Ball Valve folder into your working directory and ensure that the files are not read-only since Flow Simulation will save input data to these files. Run Flow Simulation.

2 Click File, Open. In the Open dialog box, browse to the

Ball Valve.SLDASM assembly located in the First Steps - Ball Valve folder and click Open (or double-click the assembly). Alternatively, you can drag and drop the Ball Valve.SLDASM file to an empty area of SolidWorks window. Make sure, that the default configuration is the active one.

* This is a ball valve. Turning the handle closes or opens

the valve. The mate angle controls the opening angle.

3 Show the lids by clicking the features in the FeatureManager design tree (Lid <1> and Lid <2>).

* We utilize this model for the Flow Simulation simulation without many significant

changes. The user simply closes the interior volume using extrusions we call lids. In

this example the lids are made semi-transparent so one may look into the valve.

Create a Flow Simulation Project

1 Click Flow Simulation, Project,

Wizard.

2 Once inside the Wizard, select Create

new in order to create a new

configuration and name it Project 1.

* Solidworks Flow Simulation will create a new configuration and store all data in a

new folder.

Click Next.

3 Choose the system of units (SI for this

project). Please keep in mind that after

finishing the Wizard you may change

the unit system at any time by clicking

Flow Simulation, Units.

* Within Flow Simulation, there are

several predefined systems of units. You

can also define your own and switch

between them at any time.

Click Next.

4 Leave the default Internal analysis type.

Do not include any physical features.

*We want to analyze the flow through the

structure. This is what we call an internal

analysis. The alternative is an external

analysis, which is the flow around an

object. In this dialog box you can also

choose to ignore cavities that are not

relevant to the flow analysis, so that Flow

Simulation will not waste memory and

CPU resources to take them into account.

*Not only will Flow Simulation calculate the fluid flow, but can also take into account

heat conduction within the solid(s) including surface-to-surface radiation. Transient

(time dependent) analyses are also possible. Gravitational effects can be included for

natural convection cases. Analysis of rotating equipment is one more option available.

We skip all these features, as none of them is needed in this simple example.

Click Next.

5 In the Fluids tree expand the Liquids item

and choose Water as the fluid. You can

either double-click Water or select the

item in the tree and click Add.

* Flow Simulation is capable of calculating

fluids of different types in one analysis,

but fluids must be separated by the walls.

A mixing of fluids may be considered only

if the fluids are of the same type.

*Solidworks Flow Simulation has an integrated database containing several liquids, gases and

solids. Solids are used for conduction in conjugate heat conduction analyses. You can

easily create your own materials. Up to ten liquids or gases can be chosen for each

analysis run.

*Solidworks Flow Simulation can calculate analyses with any flow type: Turbulent only, Laminar

only or Laminar and Turbulent. The turbulent equations can be disregarded if the flow

is entirely laminar. Solidworks Flow Simulation can also handle low and high Mach number

compressible flows for gases. For this demonstration we will perform a fluid flow

simulation using a liquid and will keep the default flow characteristics.

Click Next.

6. Click Next accepting the default wall

conditions.

* Since we did not choose to consider heat

conduction within the solids, we have an

option of defining a value of heat

conduction for the surfaces in contact with

the fluid. This step is the place to set the

default wall type. Leave the default

Adiabatic wall specifying the walls are

perfectly insulated.

*You can also specify the desired wall roughness value applied by default to all model

walls. To set the roughness value for a specific wall, you can define a Real Wall

boundary condition. The specified roughness value is the Rz value.

7 Click Next accepting the default for the initial conditions.

* On this step we may change the default settings for pressure, temperature and velocity. The closer these values are set to the final values determined in the analysis, the quicker the analysis will finish. Since we do not have any knowledge of the expected final values, we will not modify them for this demonstration.

8 Accept the default for the Result Solidworks Flow Simulation

Resolution.

* Result Resolution is a measure of the desired level of accuracy of the results. It controls

not only the resolution of the mesh, but also sets many parameters for the solver, e.g.

the convergence criteria. The higher the Result Resolution, the finer the mesh will be

and the stricter the convergence criteria will be set. Thus, Result Resolution determines

the balance between results precision and computation time. Entering values for the

minimum gap size and minimum wall thickness is important when you have small

features. Setting these values accurately ensures your small features are not “passed

over” by the mesh. For our model we type the value of the minimum flow passage as the

minimum gap size.

Click the Manual specification of the minimum gap size box. Enter the value 0.0093 m for the minimum flow passage.

Click Finish.

Design with SolidWorks flow simulation

create the intersection between a loft and a sweep in solidworks

A customer requested help creating the intersection between a loft and a sweep. He is working on a hairdryer and had already created the profiles to generate the lofted solid.

The first thing that came to mind was to just extrude the handle up to the next surface. You could also modify by adding another profile to the loft so that it would not result in multiple bodies.

Then, you can easily add any type of fillet that you want to create a nice looking transition. Shell the part out and it's done. Well, not really done, but well on your way.

Any other ideas to model this part better? Just add your comment.